Printing Buttons Using a Laser Printer

A few words about using a laser printer for your button designs.

Yes, laser printers do churn out vibrant colors, and therefore, beautiful graphics. But beauty sometimes comes at a price. So be forewarned: using a laser printer can lead to bubbly buttons.

Why does this happen? In some toners the wax can cause Mylar to slip during the button making process. Though it will vary by toner manufacturer, thick darker colors are typically more problematic.

How will I know if this has happened? There are two ways in which this can manifest. First, you may see a 1/4" bubble around the edge of your button. Additionally, these bubbles can cause the Mylar to pull away from the edge of rectangle buttons.

Still not sure if your buttons were affected by toner? If you want to test the toner theory, simply make a button with plain with paper. If there are no bubbles and it is crimped properly then the toner is usually the culprit.

Can this issue be solved? Yes. Absolutely! There are two ways to alleviate the issue:

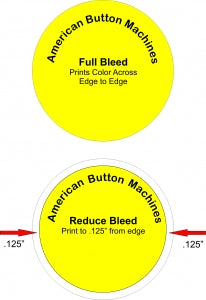

First, you can reduce the bleed edge (the solid print color) by .125” all around the edge of the button design.

An easy way to accomplish this is with Build-a-Button 5.0. Simply add the default size "accent ring" to your design and change the color to white. Bingo! Your bubble issues are a thing of the past! Not to worry, the white ring is not visible on the front of the button.

Button Bleed Edge

Or, just apply a special lubricant stick to the tapered edge of the die

How is the lubricant applied? Simply massage the product all the way around the tapered edge of the crimp die. This tapered edge is the area causing the Mylar to slip on the graphic and not wrap correctly. The lubricant renders the edge less resistant allowing the Mylar & graphic to fold perfectly into the back of the button.

| Where to apply lubricant on a round button maker | Where to apply lubricant on a rectangle button maker |

A word of caution: WD40 is no friend to the button machine die. Never, ever spray WD40, or its equivalent, on the die. Grease and oil from these sprays will leave behind a residue which will ruin your beautiful graphics. It can also cause a vacuum inside the dies making for defective buttons. A lubricant stick is your button machine's best friend for this purpose.